2001: Wild ideas — What if TAPS was topped by a bridge, boat or plane?

If the eventually true tale of TAPS wasn’t tall enough, even wilder ideas to transport Alaska’s oil from the North Slope were proposed and even attempted before TAPS was built.

Back in the early-1970s, the concept of constructing a reliable, state-of-the-art, 800-mile oil pipeline across Alaska’s unforgiving terrain on a two-year deadline – following many years of political red tape and countless starts and stops – was, well, a serious pipe dream. By 1977, though, TAPS – then the largest construction project in modern history – was complete. On June 20 of that year, it started moving oil.

Back in the early-1970s, the concept of constructing a reliable, state-of-the-art, 800-mile oil pipeline across Alaska’s unforgiving terrain on a two-year deadline – following many years of political red tape and countless starts and stops – was, well, a serious pipe dream. By 1977, though, TAPS – then the largest construction project in modern history – was complete. On June 20 of that year, it started moving oil.

Forty-five years later, some find it difficult to believe that same pipeline remains one of the world’s engineering marvels, that it’s moved more than 18 billion barrels of Alaska North Slope Crude Oil, and continues reliably operating with no end in sight.

If that eventually true tale of TAPS wasn’t tall enough, even wilder ideas to transport Alaska’s oil from the North Slope were proposed and even attempted before TAPS was built. If TAPS construction inspired the mantra, “They didn’t know it couldn’t be done,” these alternatives should have been filed under, “They should have known it couldn’t be done.”

When it comes to big ideas on modern day TAPS, Rob Annett has been on the forefront. Hired in 2001, Rob and his Appraise team of engineers are creative collaborators constantly craft ways to improve and innovate TAPS operations. “Outside-the-box thinking” doesn’t do this team justice. They’ve created pigwashing stations, introduced technology to inspect buried pump station piping without digging it up, detected pigs with gamma radiation, and even tinkered with tunneling through Atigun Pass.

We shared a few of the more interesting pre-pipeline oil movement proposals with Rob, who reviewed them with his unique perspective and provided feedback on their pros, cons, and viability.

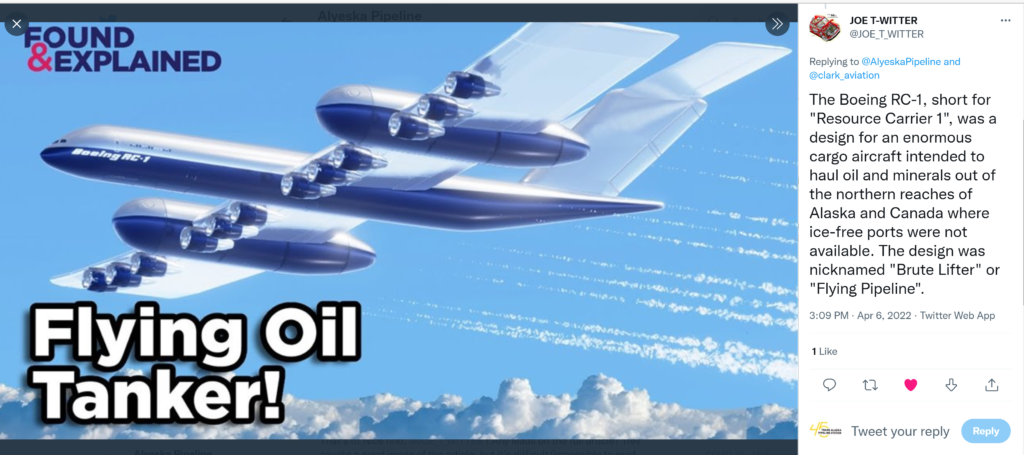

“The Flying Pipeline”

Why use thousands of people to build a complex trans-Alaska pipeline only to load the oil in sluggish shipping vessels that must battle harsh Prince William Sound conditions, when you can just peacefully fly the oil over all of it? Meet Boeing’s Resource Carrier One aka RC-1 aka the Brute Lifter aka the Flying Pipeline.

If you think TAPS is an engineering marvel, check out the Flying Pipeline’s specs: 985,000 pounds, 340-feet long with a 500-foot wingspan, 12 engines, eight sets of landing gear with 56 wheels. Yes, all of that was needed to takeoff, fly and land with its carrying capacity of 2.3 million pounds of payload (nearly 8,000-plus barrels of oil, ore or other cargo).

Inspired by the much smaller Boeing 747 freighter, the concept of the RC-1 was so immense, its cargo so heavy, and its costs to commute so substantial, it could only fly 1,000 miles. That was far enough, however, to land at a port near Alaska’s border with Canada or even somewhere in Northern Canada, where its removable oil pods could be offloaded and placed on trains or tankers. The plane would then be reloaded with empty pods and return north. Now, imagine a fleet of 50 of these Brutes (35 in action, 15 spares) each flying 18 sorties a day, 24/7 – suddenly even Prudhoe Bay’s peak production seems manageable.

Marketed as faster, more flexible in its destinations, and environmentally safer than a pipeline, the Flying Pipeline design still had its red flags, including building runways in rural areas large enough to receive them. Ultimately, Boeing never built the plane or even a prototype. Why? The same reason Alaska oil was suddenly so important that a pipeline had to be built in the ‘70s – the oil crisis basically doubled jet fuel prices and the plane plan wouldn’t pencil out to a meaningful profit.

Rob’s review: “While I like an adventure as much as the next person, and flying continuous sorties of a fleet of massive planes would qualify as an adventure, I think the tried-and-true approach of pumping oil through a pipeline is far more reliable and less costly. The pipeline is not dependent on flight rules, weather, and pilot judgement to deliver oil. I like the creativity, but the pipeline choice was far superior.”

Learn more about “The Flying Pipeline” in a story and comic book workup (source unknown); Found and Explained story and video package; Boeing RC-1 Wikipedia page

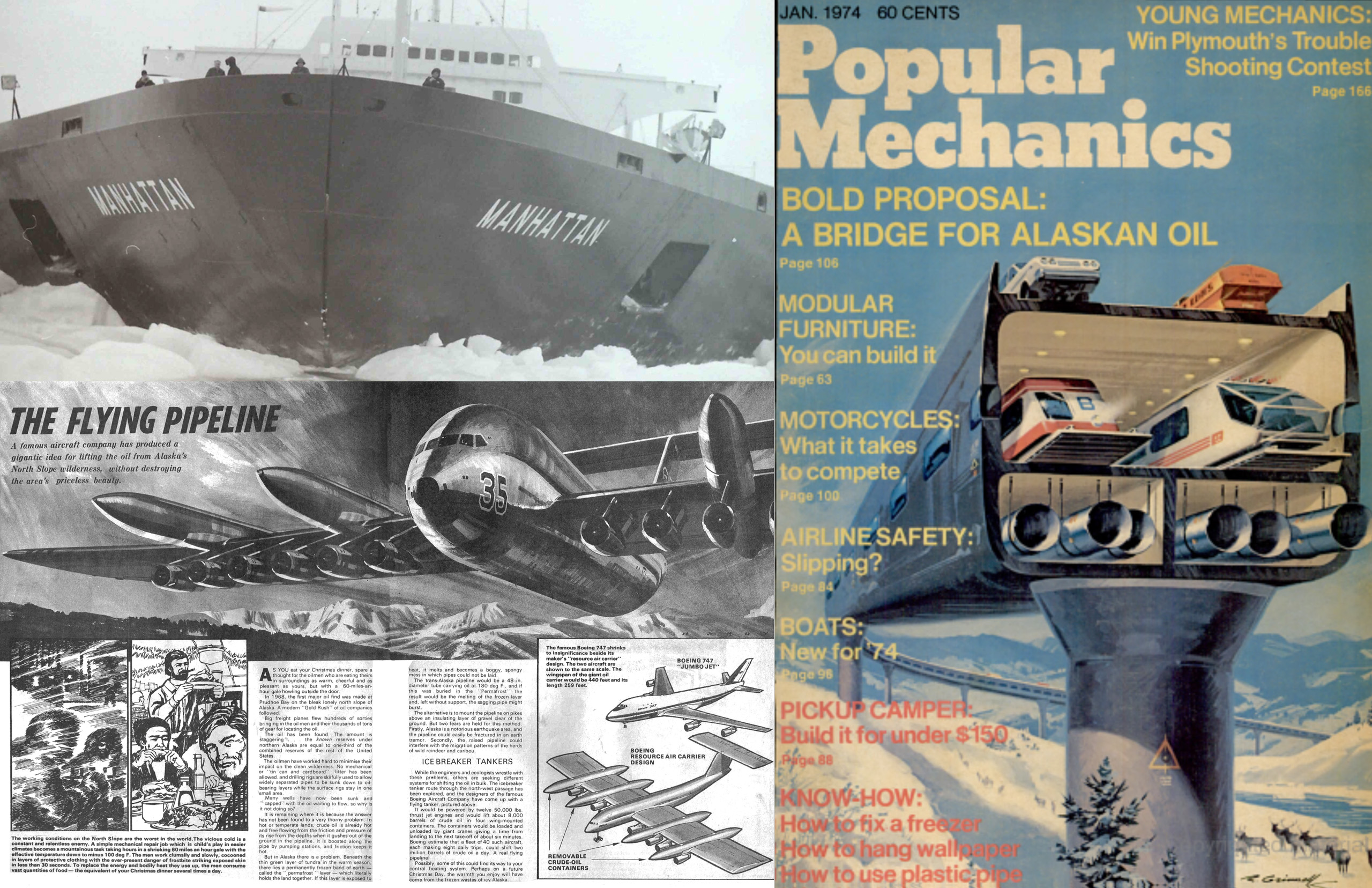

“The Bridge”

Just two months after the Trans Alaska Pipeline Authorization Act became law, the big brains at Popular Mechanics magazine produced a cover story in its January 1974 issue titled “Bold Proposal: A Bridge for Alaskan Oil.” The author, quoting the bridge concept’s engineer, surmised, “The TAPS approach represents conventional engineering and … is ‘yesterday’s way to build an oil pipeline.’”

The engineer boasted his own visionary oil movement design, one that was environmentally friendly (“save the Arctic tundra”), safer (“contain oil leakage and protect the pipe against possible sabotage”), and could potentially modernize the transportation of oil, natural gas and Alaskans, as well as serving as a conduit for communications, clean water, electricity, and more from one end of the state to the other. It was, basically, a bridge from the future.

The engineer boasted his own visionary oil movement design, one that was environmentally friendly (“save the Arctic tundra”), safer (“contain oil leakage and protect the pipe against possible sabotage”), and could potentially modernize the transportation of oil, natural gas and Alaskans, as well as serving as a conduit for communications, clean water, electricity, and more from one end of the state to the other. It was, basically, a bridge from the future.

The colossal concrete bridge known as an Integrated Pipeline Transportation (IPT) system would be set 30 feet above-ground and travel a similar route as TAPS from Prudhoe Bay to Valdez. Popular Mechanics wrote, “The IPT would be a tubular concrete structure supported at 300-foot intervals by bridge-like piers. The big tube could accommodate as many as six pipelines and could also function as a transportation artery. Its upper deck, or decks, could be used by autos, trucks and/or an electrified rail system. … (The) IPT system is designed to avoid or contain the various hazards (earthquakes, oil spills, permafrost degradation/thawing, streams crossings, wildlife interference, etc.). … The use of bridge-launching techniques minimizes access road construction necessary to reach production plant stations. These stations could be situated in areas picked to minimize adverse environmental effects. This contrasts with the 92-foot right-of-way TAPS needs for a permanent roadway and room for construction. … By including all modes of transport, including passenger, freight, communication, power, oil, gas and water lines, a single artery would serve in place of the usual proliferation of pipes, lines and roads. (And) designed for future needs. Highway lanes, for example, could be changed to rapid transit.”

Bold indeed. Even bolder, the engineer’s estimate for building nearly 800 miles of a smaller midi-version of the IPT was $6 billion – a full-sized concept would be billions more. Sure, at completion, TAPS’ final completed construction cost had ballooned to $8 billion, but it seemed downright reasonable and responsible in comparison to the bridge’s starting point. Alaska and the world were not ready for a bridge like this. We still might not be.

Rob’s review: “This concept is by far the most creative and could have been covered by the slogan: ‘As long as you’re building one pipeline … might as well build a few others and a new highway or two while you’re at it!’ The costs likely would have been higher than TAPS (which almost bankrupt some of the original Owners as it was) and the complexity would have exponentially higher. I like the elegant nature of TAPS in comparison to this alternative. But it’s intriguing to imagine the potential outsized impact this concept would have had on Interior Alaska.”

Learn more about “The Bridge” in the January 1974 Popular Mechanics cover story, “Bold Proposal: A Bridge for Alaskan Oil.”

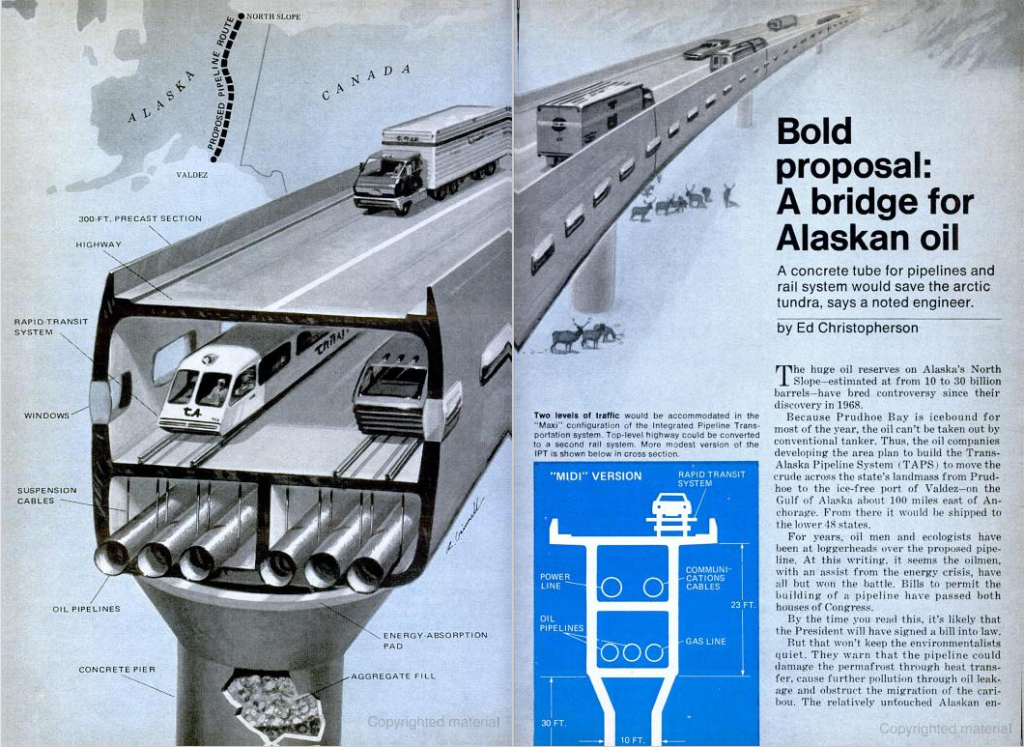

“The Boat”

A more traditional plan to complement North Slope oil transportation in conjunction with TAPS, instead of competing against it, was spawned and tested years before pipeline construction. Tankers would take on oil in Prudhoe Bay, then travel 5,000 miles across the ice-packed-and-isolated Northwest Passage to East Coast refineries and markets, expanding the oil’s reach.

In the 1977 book “800 Miles to Valdez” by James P. Roscoe, the author detailed expeditions to test the viability. In Sept. 1969 and again in 1970, “the S.S. Manhattan churned out of the Delaware River near Philadelphia, bound for the top of the world. The 115,000-ton oil tanker, 1,005 feet long, had been rebuilt into a highly advanced Arctic cargo ship: a partially double-hulled tanker that was also an icebreaker. The $50 million research project (was) sponsored by Humble with support from ARCO and British Petroleum. … On a cost basis, in 1969, the two transport systems were rated as within range of each other.

In the 1977 book “800 Miles to Valdez” by James P. Roscoe, the author detailed expeditions to test the viability. In Sept. 1969 and again in 1970, “the S.S. Manhattan churned out of the Delaware River near Philadelphia, bound for the top of the world. The 115,000-ton oil tanker, 1,005 feet long, had been rebuilt into a highly advanced Arctic cargo ship: a partially double-hulled tanker that was also an icebreaker. The $50 million research project (was) sponsored by Humble with support from ARCO and British Petroleum. … On a cost basis, in 1969, the two transport systems were rated as within range of each other.

“The voyages of the Manhattan were widely publicized. … The Northwest Passage’s ancient ice floes proved formidable adversaries. Time and again on the first voyage, the big tanker was trapped in encircling ice and freed by Canada’s icebreaker, the John A. MacDonald. Initially bound around Alaska, the Manhattan struggled just to reach Prudhoe Bay. It took aboard a ceremonial drum of North Slope oil, went on a short distance to Point Barrow, and then headed back for the Atlantic. On the return trip, there was some ominous damage. Trapped again in the pack ice, the tanker was backing astern when a projection of steely ice ripped a long gash in the single-hulled section of the ship below the waterline.

“The Manhattan finished this trip and its second voyage safely. Future Northwest Passage tankers in any case would have had completely double-walled hulls against such danger. But there were doubts. An oil spill in the Arctic would be catastrophic, for the oil would just stay there without decomposing for years. Also, the constant uncertainty of offshore ice conditions raised questions about the year-round capability that North Slope production would require.”

Ultimately, the secondary source of North Slope crude transportation was put on ice. The ventures strengthened the case for TAPS: “The pipeline, in any case, was not a question. From the start of 1969 on, it was a committed project. … Yes, there were other solutions … (but) the development of a major oil source like Alaska, and the building of a pipeline to carry it, becomes necessary.”

Perhaps the idea could be resurrected today. The combination of technology, improved shipbuilding, and climate change in the Arctic has led to passenger cruise ships occasionally traveling the Northwest Passage, floating by the North Slope on its way to the new hospitality hotbed port of Nome.

Rob’s review: “Aside from a pipeline, this concept seems like a frontrunner – especially compared to the others proposed. Marine shipping is more of a known entity, costs are somewhat predictable, and if it were just open water, it would be very reliable, just an extension of what we do now from Valdez to the West Coast. In fact, this concept was revisited by TAPS employees over 10 years ago as a part of the Future Strategy Team, where it was acknowledged that climate change might lessen the ice obstacles. The fleet build-out costs and remaining uncertainties with passage discounted the idea then, but if throughput were low enough it might make more sense. Until then, our pipeline is a clear winner!”

Learn more about the S.S. Manhattan’s Northwest Passage voyages in Ned Rozell’s profile of a member of the S.S. Manhattan crew (and his future coworker at UAF’s Geophysical Institute) and a first-person account of a crew member, who shares his perspective and photos

READ MORE 45TH ANNIVERSARY IMAGINATION & INGENUITY STORIES:

1984: TAPS Telecoms Then & Now with Dana Orr

1988: Throughput peak: TAPS tops 2 million barrels a day

1992: New otter, bird facilities support rescue, care